| Bonds | Features | Application | Grinder | Industries |

| B109 | Economy Resin Bond Wet & Dry grinding Sharp | Tool Sharpening | Manual Semi-Automatic | Woodworking Metalworking Knife Blades |

| B102 | Advanced resin bond Wet and dry grinding Durable | Tool Grinding, Tool Sharpening | Manual Semi-Automatic Full-Automatic | Woodworking Metalworking Knife Blades |

| B201 | Universal Bond for Wet grinding Wet Grinding Standard bond for quantity grinding | Cylindrical Grinding Surface Grinding | Manual Semi-Automatic | Cutting Tools, Mould & Dies, Knife & Blades Oil & Gas |

| B202 | Advanced Bond for Wet grinding Wet Grinding Advanced bond for quantity grinding | Cylindrical Grinding Surface Grinding | Manual Semi-Automatic | Cutting Tools, Mould & Dies, Knife & Blades Oil & Gas |

| B601 | Super Resin Bond for Tool grinding Bond for tool fluting & Gashing on CNC Dural Bond | Tool fluting Tool Gashing Edge Clearing | Full-Automatic CNC | Cutting Tools Metalworking |

| MH11 | Hybrid Bond Most Durable Free cut on tool fluting Bond for tool fluting & Gashing | Tool fluting Tool Gashing Tool Profiling | Full-Automatic CNC | Cutting Tools Metalworking |

| CODE | Abrasives | Grits | Concentration | Hardness |

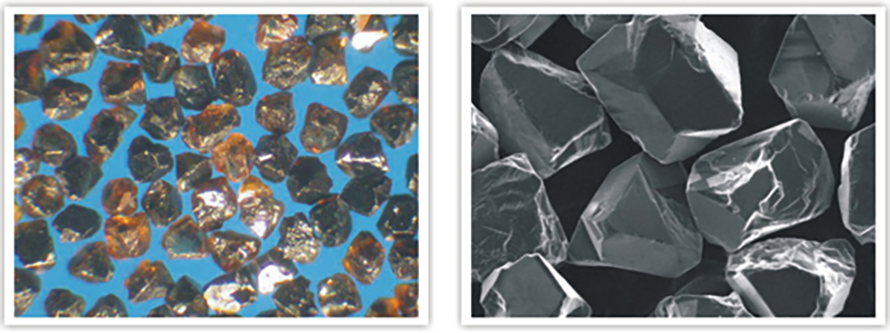

| D | Synthetic Diamond Mono-Crystal Type I | 80, 100 Roughing | 50 Most economical For broad area of contact | H Extremely Soft Sharp |

| SD | Synthetic Diamond Mono-Crystal Type II | 120 Roughing/cutting-off | 75 Improved on Wheel Life Improved on Wheel Sharp | K Soft Sharp |

| SDC | Synthetic Diamond Mono-Crystal Metal Coating | 150 – Combined roughing and finishing | 100 Standard Concentration | N Standard |

| DP | Synthetic Poly Diamond | 180 – Improving finish | 125 • Form holding • For high volume grinding | O HARD |

| DPC | Synthetic Poly Diamond Metal Coating | 220, 320, 400 for finishing | 150 Quantity Grinding Super wheel life | |

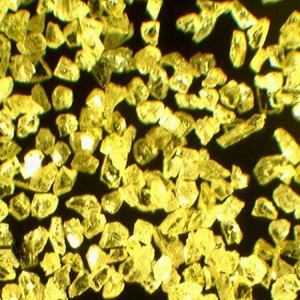

| B | CBN Abrasives | 600, 800, 1000 1500 for polishing | ||

| BC | CBN With Coating |

| Features | Grinding Method | Industry |

| Economy - Cheapest Bond | OD Grinding | Tool Grinding & Sharpening |

| High Efficiency | Surface Grinding | Woodworking Tools |

| High Stock Removing Rates | Profile Grinding | Oil & Gas Tool |

| Good durability | ID Grinding | Knife & Blades |

| Good Shape retaining ability | Cutting | Mould and Die |

| CBN is used to grind ferrous materials. |

| • High-speed tool steels |

| • Die steels |

| • Hardened carbon steels |

| • Alloy steels |

| • Aerospace alloys |

| • Hardened stainless steel |

| • Abrasion-resistant ferrous materials |

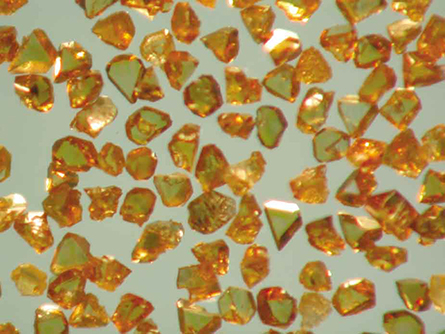

| In general, diamond is used to grind non-ferrous materials |

| • Cemented carbide(Tungsten Carbide) |

| • Glass |

| • Ceramics |

| • Fiberglass |

| • Plastics |

| • Stone |

| • Abrasives |

| • Electronic components and materials |