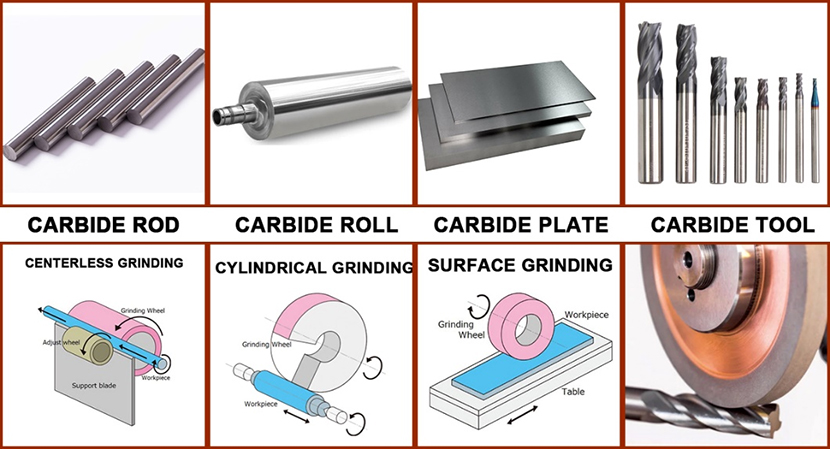

Tungsten Carbide (Cemented Carbide) is a very hard non-ferrous metal, diamond grinding wheels is the ideal choice to grind it. Because Tungsten carbide is very hard, usually from HRC 60 to 85. So traditional abrasive grinding wheels can’t grind well. Diamond is the hardest abrasives. A resin bond diamond grinding wheels can free grind tungsten carbide. No matter tungsten carbide raw materials (rod, plate, stick or disc), Tungsten carbide tools, or Tungsten carbide coating, our diamond grinding wheels can all grind fast and with excellent finishes.

1. Fast grinding. Comparing conventional abrasive wheels, Diamond wheels grind faster. When you do quantity grinding, the fast grinding help you save a lot of time. Saving time and help you make more profits. 2. Excellent finishes If a grinding wheel is not sharp, chatter waves or lines will appear on workpiece. A sharp diamond grinding wheels will help you solve these problems and bring an excellent surface finish. 3. Cool Grinding Due to highly efficient grinding, less heat generated. And the aluminum body can help heat spread quickly. 4. Long lifespan Due to the high hardness of diamond abrasives, Diamond wheels has extra longer lifespan than conventional abrasive wheels. 5. Less dressing A sharp diamond grinding wheels needs less dressing

1. Fast grinding. Comparing conventional abrasive wheels, Diamond wheels grind faster. When you do quantity grinding, the fast grinding help you save a lot of time. Saving time and help you make more profits. 2. Excellent finishes If a grinding wheel is not sharp, chatter waves or lines will appear on workpiece. A sharp diamond grinding wheels will help you solve these problems and bring an excellent surface finish. 3. Cool Grinding Due to highly efficient grinding, less heat generated. And the aluminum body can help heat spread quickly. 4. Long lifespan Due to the high hardness of diamond abrasives, Diamond wheels has extra longer lifespan than conventional abrasive wheels. 5. Less dressing A sharp diamond grinding wheels needs less dressing