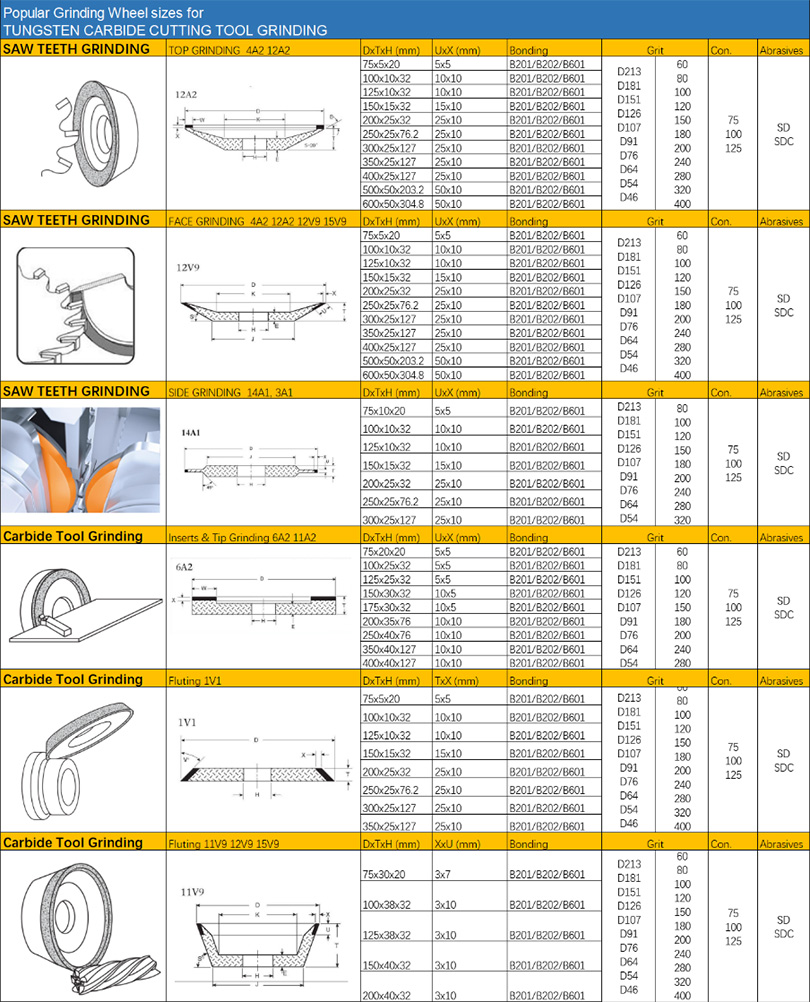

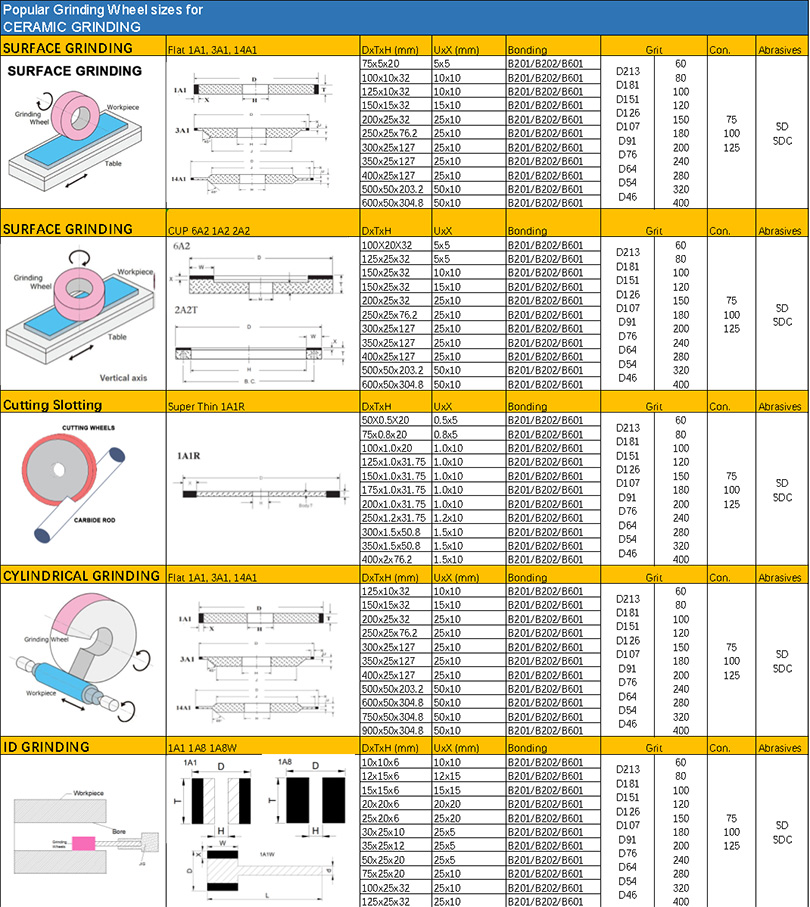

Surface Treatment after coating 1.OD Cylindrical Surface – Grinding, Polishing 2.ID Inner Hole - Grinding and Honing For Inner holes after coating, use ID grinding wheels on jig grinder to grind is common method. Well, you have strict demands and narrow tolerances requests, honing will be the right Choice 3.Flat Surface – Grinding, Lapping For coating flat surface, use diamond grinding wheels to grind, use synthetic diamond abrasive to lapping1.Fast grinding. Comparing conventional abrasive wheels, Diamond wheels grind faster. When you do quantity grinding, the fast grinding help you save a lot of time. Saving time and help you make more profits. 2.Excellent finishes If a grinding wheel is not sharp, chatter waves or lines will appear on workpiece. A sharp diamond grinding wheels will help you solve these problems and bring an excellent surface finish. 3.Cool Grinding Due to highly efficient grinding, less heat generated. And the aluminum body can help heat spread quickly. 4.Long lifespan Due to the high hardness of diamond abrasives, Diamond wheels has extra longer lifespan than conventional abrasive wheels. 5.Less dressing A sharp diamond grinding wheels needs less dressing

Surface Treatment after coating 1.OD Cylindrical Surface – Grinding, Polishing 2.ID Inner Hole - Grinding and Honing For Inner holes after coating, use ID grinding wheels on jig grinder to grind is common method. Well, you have strict demands and narrow tolerances requests, honing will be the right Choice 3.Flat Surface – Grinding, Lapping For coating flat surface, use diamond grinding wheels to grind, use synthetic diamond abrasive to lapping1.Fast grinding. Comparing conventional abrasive wheels, Diamond wheels grind faster. When you do quantity grinding, the fast grinding help you save a lot of time. Saving time and help you make more profits. 2.Excellent finishes If a grinding wheel is not sharp, chatter waves or lines will appear on workpiece. A sharp diamond grinding wheels will help you solve these problems and bring an excellent surface finish. 3.Cool Grinding Due to highly efficient grinding, less heat generated. And the aluminum body can help heat spread quickly. 4.Long lifespan Due to the high hardness of diamond abrasives, Diamond wheels has extra longer lifespan than conventional abrasive wheels. 5.Less dressing A sharp diamond grinding wheels needs less dressing

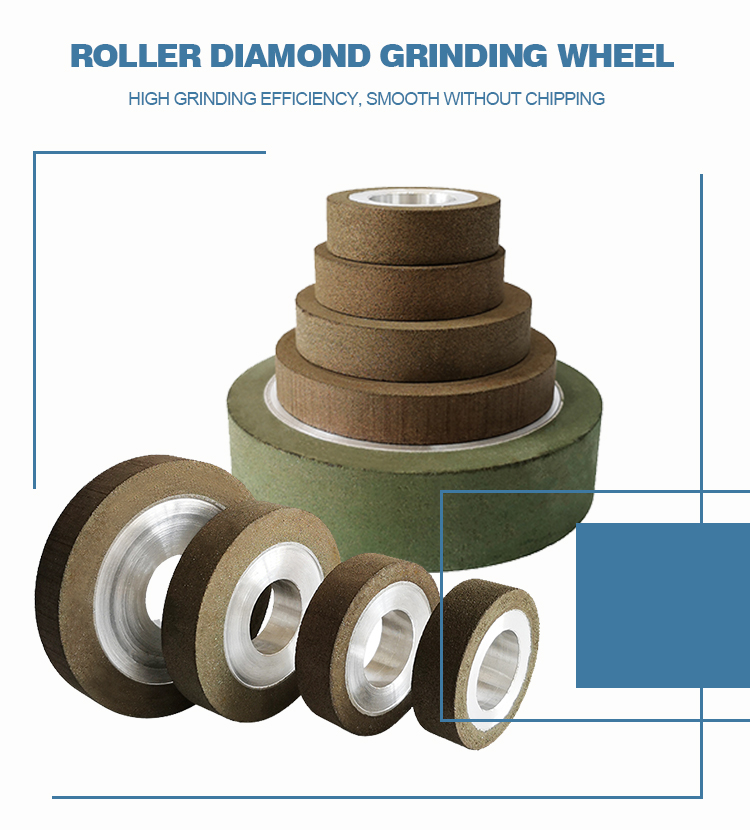

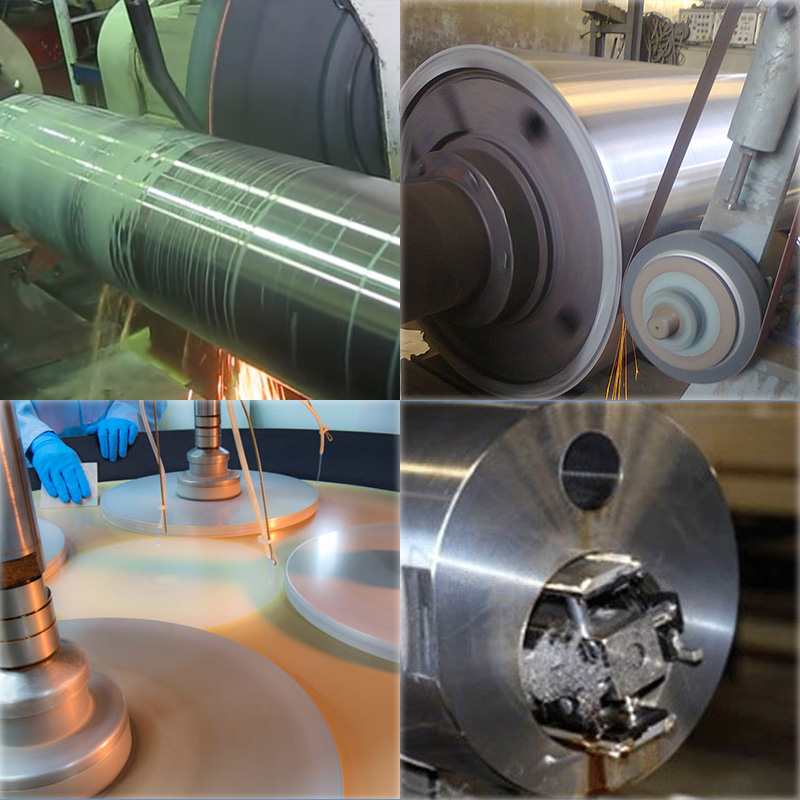

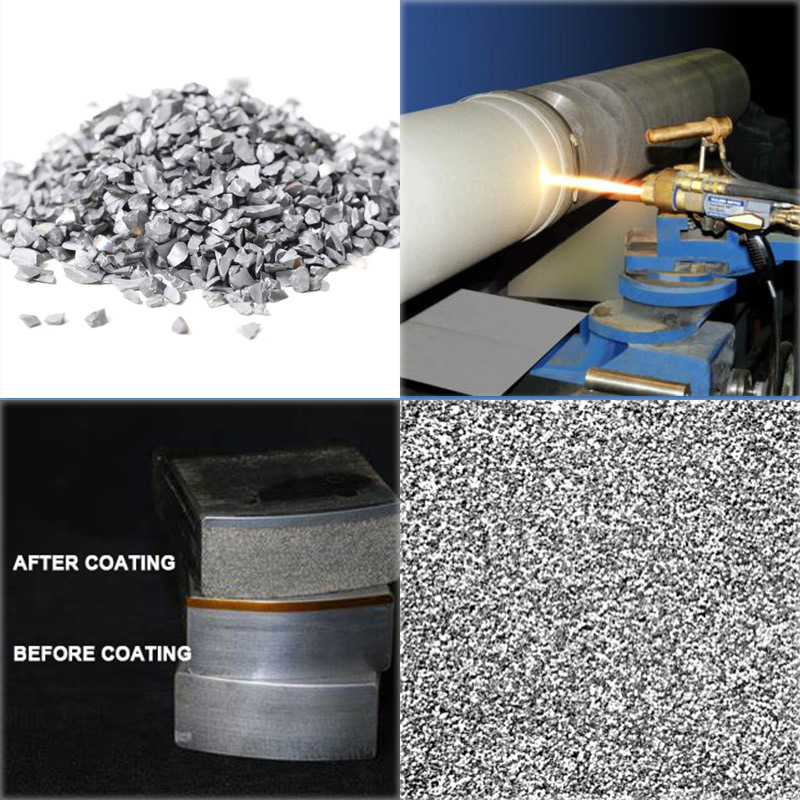

Advantage of Chrome Coating, Tungsten Carbide Coating 1.High Wear Resistance 2.Anti-rust 3.Anti-corrosion 4.Anti-oxidation Chrome Coating, Tungsten Carbide Coating Method 1.HOVF Thermal Spraying 2.Wire Arc Spraying 3.Flame SprayingRZ company can supply diamond grinding wheels, diamond belt, honing stones and honing tools. 1.Diamond Wheels for cylindrical grinding 2.Diamond Belt for Cylindrical grinding and Polishing 3.Diamond Wheels for ID inner hole Grinding 4.Diamond honing tools for Inner hole honing

Advantage of Chrome Coating, Tungsten Carbide Coating 1.High Wear Resistance 2.Anti-rust 3.Anti-corrosion 4.Anti-oxidation Chrome Coating, Tungsten Carbide Coating Method 1.HOVF Thermal Spraying 2.Wire Arc Spraying 3.Flame SprayingRZ company can supply diamond grinding wheels, diamond belt, honing stones and honing tools. 1.Diamond Wheels for cylindrical grinding 2.Diamond Belt for Cylindrical grinding and Polishing 3.Diamond Wheels for ID inner hole Grinding 4.Diamond honing tools for Inner hole honing