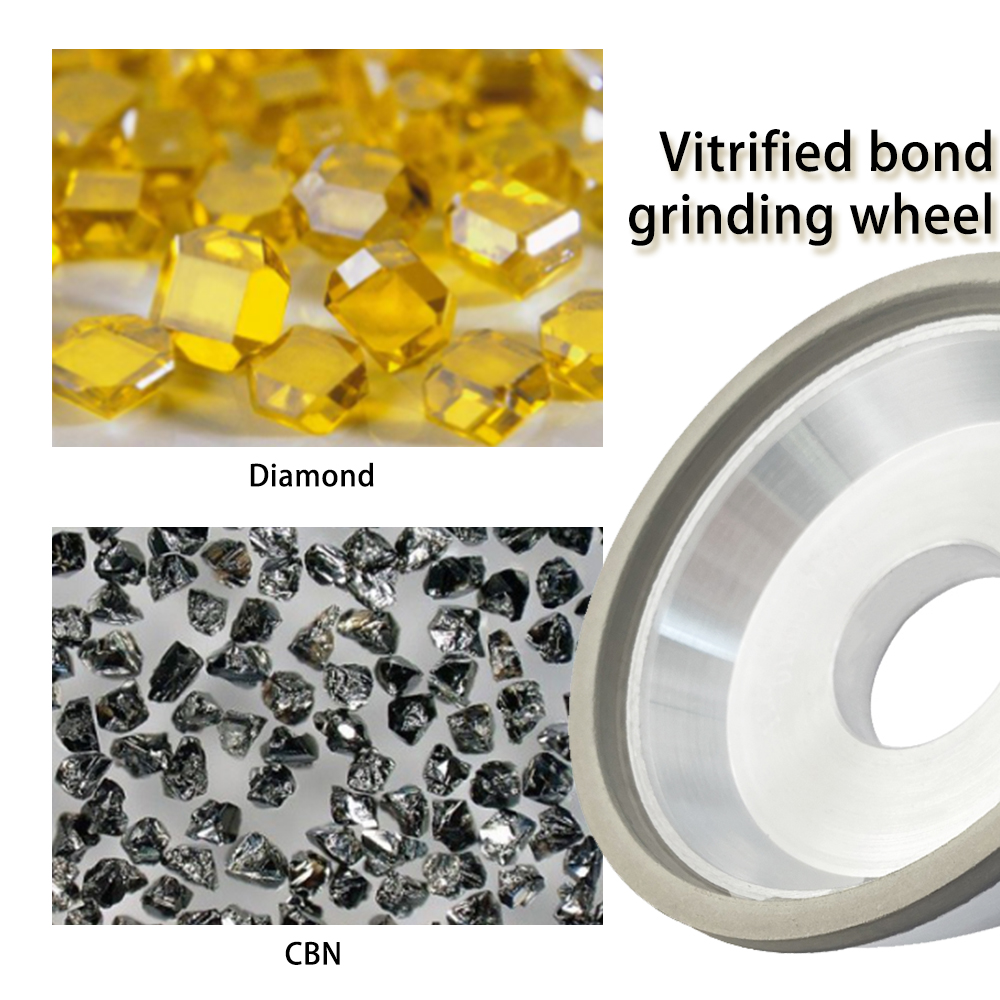

About the grinding wheel :

Vitrified bonds allow the wheel to be very rigid, strong and porous. These characteristics each provide many benefits to the wheel. Having a rigid wheel allows for a strong cutting performance and increased grinding speed. Another added benefit of the vitrified bond is its porous character. The porosity of the wheel allows coolant to penetrate between the work piece and the wheel to effectively remove heat from the point of contact, and we all know that any reduction in heat generated while grinding will extend the life of the product.1. Highest grinding efficiency 2. Increase the feed rate 3. High sharpness 4. Beautiful appearance 5. No trimming tools required 6. Less fever 7. Excellent dynamic balance control. 8. It can cut superhard workpieces. 1. - For PCD, PCBN super-hard cutting tools grinding 2. - For PCBN cutting tools grinding 3. - For CVD cutting tools grinding 4. -For single natural diamond tools grinding 5. - For polycrystalline diamond compacts ( PDC ) grinding 6. - For carbide alloy products grinding 7. - For ceramic product grinding1. What are your prices? Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information. 2.Do you have a minimum order quantity? Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website 3.Can you supply the relevant documentation? Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required. 4.What is the average lead time? For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so. 5.What kinds of payment methods do you accept? You can make the payment to our bank account, Western Union or PayPal: For big orders, partial payment is also acceptable.

|